Quality Systems

Latest News

Latest Videos

More News

As advanced manufacturing technologies reshape pharmaceutical production, the Qualified Person (QPs) must evolve from a traditional document reviewer into a digitally fluent leader capable of navigating complex data ecosystems, real-time analytics, and automated control systems. This article presents a holistic framework for “Certification by Design,” highlighting how QPs can ensure compliant, agile, and science-based batch release in the era of Industry 4.0.

In this episode of the Ask the Expert video series, Susan J. Schniepp, Regulatory Compliance Associates (RCA), Siegfried Schmitt, Parexel, and Anita Michaels, RCA, explain how CDMOs can best handle regulatory inspections and client expectations.

The European Union aims to become the most attractive destination for clinical research.

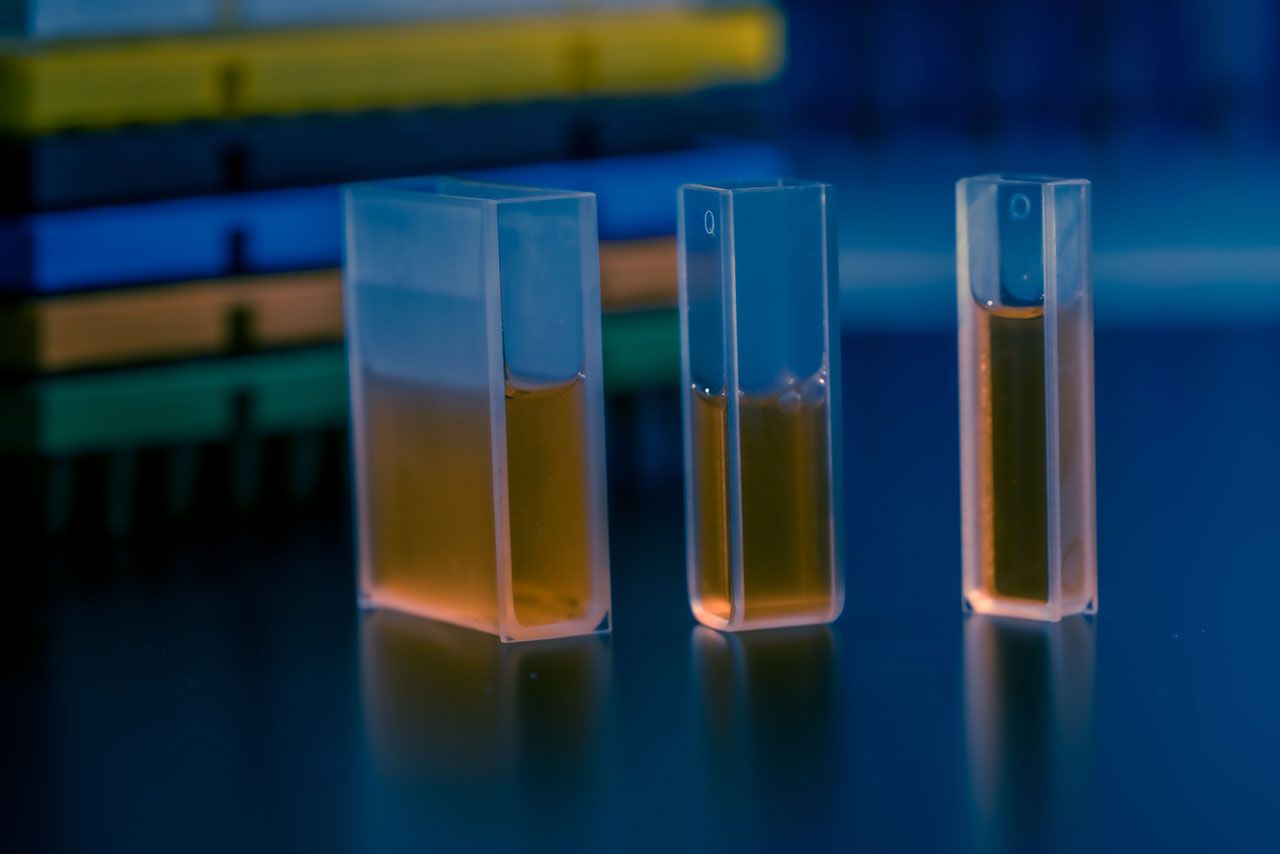

In a poster presentation at AAPS PharmSci 360, Eda Fenercioglu, a scientist at Pfizer, outlines a streamline workflow for identifying and mitigating visible particles in biologic drugs.

Frank Romanski of Lonza Capsugel dives into the excipient side of manufacturing and the emerging prevalence of digitalization.

Vishal Mukund Sonje, Vaccine Manufacturing Lead, CEPI, talks about the challenges that arise in the manufacturing of vaccines in various global regions.

Pharma companies are focusing on sustainability efforts to meet client expectations, environmental audits, and climate pressures.

Pharmaceutical Technology® spoke with Dr. Weite Oldenziel, CEO of Ofichem, before CPHI Frankfurt 2025 to get his perspective on the API market and why it is important to qualify API suppliers.

Pharmaceutical packaging plays an important role in sustainability efforts. Maija Pohjakallio, VP, Climate and Circular Economy, Metsä Group, explains how fiber-based packaging can help with these efforts.

Real-world data can be utilized to ensure quality and effectiveness of drug products.

In this episode of the Ask the Expert video series, Susan J. Schniepp, Regulatory Compliance Associates, and Siegfried Schmitt, Parexel, give their opinions on why those working in the pharmaceutical industry should lend their voices to draft regulations.

This article outlines common CMC problems that are obstacles that steal momentum and create costly detours in the development or orphan drugs.

The European Union aims to become the most attractive place for life science by 2030.

The increasing diversity and complexity of injectable drug products is driving innovation.

Pharmaceutical Technology® spoke with Juliana Maynard, PhD, Head of Translational Imaging at Medicines Discovery Catapult, to find out what makes radiopharmaceuticals unique and how MDC’s collaboration with Crown Bioscience can help developers of these treatments for cancer.

Siegfried Schmitt, PhD, vice-president, Technical at Parexel, answers questions on the use and benefits of real-world evidence for small-molecule and large-molecule drug development.

A draft reflection paper on patient experience data is up for public consultation until Jan. 31, 2026.

FDA's Center for Biologics Evaluation and Research has released updated draft recommendations for sponsors of cell therapies, gene therapies, and tissue products.

The FDA draft guidance "Considerations for Complying with 21 CFR 211.110" raises points to consider regarding drug products made using advanced manufacturing, batch uniformity, drug product integrity, and how manufacturers can incorporate process models into control strategies.

The dispute shines a light on the vulnerability of long-established drugs to renewed safety scrutiny: Even when causal evidence is lacking, observational findings can influence policy and public perception.

EMA states the new variations guidelines will streamline lifecycle management and make processing variations quicker.

CDC panel shifts vaccine policy by discouraging combined MMRV shot for young children due to increased febrile seizure risk.

Pharmaceutical Technology® spoke with Todd Sprouse, associate director, Analytical Services, and Erik Feldmann, PhD, principal technical advisor, Client Solutions & Proposals, both with Cambrex, to find out more about the challenging situation.

Misleading promotions of GLP-1 and compounded semaglutide products are drawing renewed regulatory scrutiny over risk disclosure and safety messaging.

Bram Baert, global head of Regulatory Affairs at Lonza CHI, gives his perspective on the impact of the EC’s decision on the use of TiO2 in drug products.