Optimizing water and HVAC systems can reduce resource use in all pharma facilities, and, for biopharma manufacturing, the supply chain of consumables should be evaluated.

Jennifer Markarian is manufacturing reporter for Pharmaceutical Technology.

Optimizing water and HVAC systems can reduce resource use in all pharma facilities, and, for biopharma manufacturing, the supply chain of consumables should be evaluated.

A QbD approach can address manufacturing complexities in transdermal patch manufacturing.

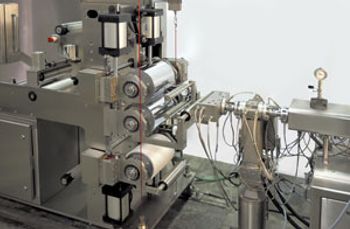

Medherant has developed an improved instrument for testing drug release from transdermal patches.

An enhanced instrument for testing drug release from transdermal patches has been developed by Medherant.

Optimizing water and HVAC systems can reduce resource use in all pharma facilities, and, for biopharma manufacturing, the supply chain of consumables should be evaluated.

Rutgers University-based C-SOPS annual meeting described advances in continuous manufacturing understanding and future plans for broader education efforts.

Water shortages, testing expenses, and effluent treatment are important issues for pharma manufacturers.

Support from FDA, a best practice guide, collaborative research, and new facilities signify progress in solid-dosage continuous manufacturing.

Continuous twin-screw granulation offers several options for increasing production scale. Thermo Fisher Scientific explains factors to consider in scale-up projects for manufacturing oral solid-dosage drugs.

Everyone from IT departments through to manufacturing line personnel should be aware of cybersecurity threats and how to prevent attacks.

Characterization of the product and process is key for process development and scale-up of topical drug manufacturing using a QbD approach.

The advantages of single-use systems become clear as they become more broadly implemented.

Industry experts discuss the single-use revolution and changes to upstream and downstream processing equipment.

Oral solid-dosage and parenteral drug manufacturing equipment and systems have made great strides in safety and efficiency.

New ADC therapies must overcome manufacturing challenges to reach market.

As commercial manufacturing considers single-use materials, a look shows how industry moved to the technology.

The need for flexibility and higher quality are driving advances in parenteral manufacturing and fill/finish equipment.

At an industry seminar hosted by Leistritz Extrusion, experts explained the use of extrusion equipment to mix polymeric excipients with APIs for solubility enhancement and for multifunctional and specialty dosage forms, including implants.

Although technical paths for continuous solid-dosage manufacturing have been laid out and equipment and control systems have been developed, industry is slow to move forward.

To prevent failure during lengthy use, tube life should be monitored and a preventive maintenance program enacted.

Soft sensors are powerful tools that can be used along with spectroscopic instruments in on-line measurement.

Conferences focused on continuous solid-dosage manufacturing aim to spread the word about technical capabilities and alleviate perceptions of regulatory uncertainty.

A Keynote Series includes presentations by experts in serialization and traceability, continuous solid-dosage manufacturing, cleaning validation, and post-approval changes.

Moving to the next level of productive, reliable performance in bio/pharmaceutical manufacturing requires a willingness to make changes and create a quality culture.

Quality metrics are used by FDA and by bio/pharma companies to evaluate manufacturing and fuel continuous improvement efforts.

Pharmaceutical Technology spoke with Frank Generotzky, plant manager for Baxter BioPharma Solutions’ Halle, Germany facility, about operational excellence at the site.

Improved process analytical technology and new ways of thinking seek to enhance measurement and control for next-generation pharmaceutical manufacturing.

Soft sensors are powerful tools that can be used along with spectroscopic instruments in on-line measurement.

Pump systems must be designed to meet the needs of specific processes, including preventing cross-contamination and damage due to shear forces.

To prevent failure during lengthy use, tube life should be monitored and a preventive maintenance program enacted.