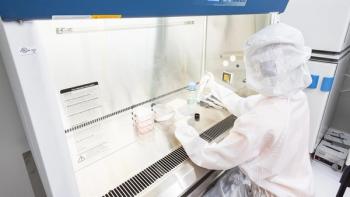

Testing cleanroom garments while in use and during daily cleanroom operations is vital for contamination control.

Testing cleanroom garments while in use and during daily cleanroom operations is vital for contamination control.

G-CON’s signature standardPOD cleanrooms will now be available in Europe.

Moderna and Thermo Fisher Scientific have formed a collaboration to leverage dedicated commercial fill/finish manufacturing capacity in the US for mRNA vaccines and therapies.

SKAN’s new Cellana isolator is designed for GMP manufacturing of ATMPs.

Fareva plans to use blow-fill-seal equipment and ApiJect’s prefilled injector technology to create fill/finish capacity in France.

New processes, automation, and digitalization were highlighted in 2021.

Isolators move into smaller-volume processes, including cell and gene therapy manufacturing.

Sartorius will invest approximately €270 million (US$305 million) to expand its biopharmaceutical manufacturing activities in South Korea’s biopharm hub.

Jordi Serrat, Product & Technology Director, Azbil Telstar talks about the role of disruptive and digital technologies in aseptic processing.

Rafael Beaus, Global Consultancy Manager, Azbil Telstar, discusses Annex 1 and trends in aseptic production.

Luke Stockhausen, Lead Process Engineer, CRB, talks about technological advances, processing line changes, and new solutions to overcome challenges in aseptic processing.

Richard Denk, Senior Consultant Aseptic Processing and Containment, SKAN AG, discusses the evolution of aseptic processing with a particular focus on isolators.

Trends and technologies in pharmaceutical manufacturing were highlighted on the show floor and in the conference sessions on the INTERPHEX Innovation Stage.

Patrick Nieuwenhuizen, Senior Manager/Consultant, PharmaLex, discusses changes to regulatory requirements, quality risk management, audits, and operational considerations of aseptic processing.

TCR² Therapeutics will add a second clean room to their manufacturing operations.

SGS’s new Antwerp, Belgium, clinical research site will house both clinical trial patients and good manufacturing practice drug manufacturing, and its Glasgow, UK, biosafety testing site now has increased testing capacity.

A new GMP facility in Raleigh, NC, and a starting materials facility in Paris, France, give Cellectis end-to-end, in-house manufacturing capacity for its UCART product candidates.

Smiths Detection has confirmed that the Bioflash air sampler can detect Beta, Gamma, Kappa, Delta, and Delta plus variants.

Conventional and robotic automation inside closed systems reduces risk.

Susan J. Schniepp, distinguished fellow at Regulatory Compliance Associates, answers some commonly asked questions about aseptic processing.

NewAge Industries has completed a plant expansion that added new cleanrooms to its headquarters in Southampton, Pa.

Lonza’s investment in its Stein and Basel facilities in Switzerland aims to expand its overall drug product development and manufacturing services.

CPC’s MicroCNX Series Connectors provide an alternative to tube welding at small tubing sizes.

Microbial experts should employ proactive practices on the manufacturing floor, rather than relying on testing.

Lonza plans to establish drug product manufacturing capabilities at is site in Guangzhou, China, to produce clinical trial and commercial supply in the country.