Advances in chemical synthesis are enabling greener, more cost-efficient processes for API manufacturing.

Cynthia A. Challener is a contributing editor to Pharmaceutical Technology.

Advances in chemical synthesis are enabling greener, more cost-efficient processes for API manufacturing.

Efficient synthesis of complex cannabinoids is possible while avoiding marijuana cultivation.

The decision to use disposable bioreactors is now driven by commercial rather than technological considerations.

Advances in equipment, instrument, and control systems are enabling online monitoring of continuous API manufacturing.

Advances in chemical synthesis are enabling greener, more cost-efficient processes for API manufacturing.

Researchers continue efforts to overcome challenges of effective oral delivery of biologic drugs.

Advances in process analytical technology have been achieved, but significant challenges remain.

Effective solutions for overcoming the high molecular weight, hydrophilicity, and instability of large biomolecules have yet to be identified.

Meeting evolving global requirements for excipients requires close collaboration between pharmaceutical companies and excipient suppliers.

Mass spectrometry plays and important role in advancing on biologic drug development and manufacturing, but limitations still exist.

Drug manufacturers need to work closely with excipient suppliers to ensure supply chain safety.

Although limitations must be overcome, mass spectrometry is having a great impact on biologic development and manufacturing.

FDA issued approvals for less than half the number of new drugs in 2016 compared with 2015.

Alternatives to expensive palladium catalysts are gaining acceptance for commercial API synthesis.

As of mid-December, less than half the number of new drug approvals were issued by FDA in 2016 compared with 2015.

Previous hesitation by pharma industry to use cocrystals may change with FDA’s new guidance that classifies cocrystals APIs.

Non-precious-metal catalysts are increasingly employed for commercial API synthesis.

Pressures to accelerate current and next-gen therapies are challenging traditional microbiological testing models.

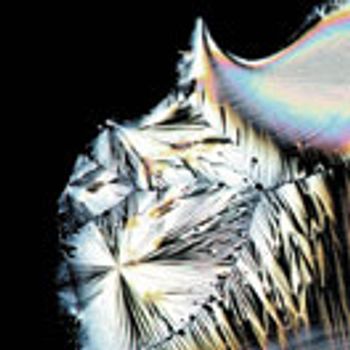

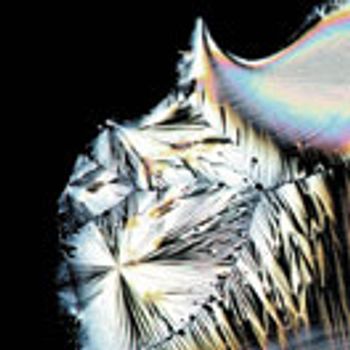

New catalysts show promise for pharmaceutical intermediate and API synthesis.

FDA redefines cocrystals as APIs and not drug-product intermediates.

A simpler, cost-effective method for the preparation of fluorolactams may be suitable for scale-up.

Researchers develop catalysts that mediate complex transformations under conditions appropriate for commercial manufacture.

Drug companies and CDMOs seeking greener routes to the production of complex APIs may look to biocatalysis.

Researchers at GlaxoSmithKline report a greener and lower-cost route to chiral fluorolactams that is suitable for scale up.

Recent research of efficient chiral synthesis technologies reveals potential uses in API manufacturing.

Enzymatic catalysis offers pharma manufacturers a way to implement the Principles of Green Chemistry.

Multiple methods are required for detecting and removing protein impurities.

Research efforts around the world are demonstrating that the application of flow chemistry for small-molecule API synthesis.

Recent chiral advances demonstrate promise for API synthesis.

Effective harvesting and purification processes play an essential role in ensuring that biopharmaceutical manufacturing processes provide biologic drug substances with uniform and consistent properties.