The lipid-based method provides a tool for delivery of highly potent, poorly soluble, and unstable APIs. And new in-process capsule printing and shell technologies expand softgels’ applications further.

Cynthia A. Challener is a contributing editor to Pharmaceutical Technology.

The lipid-based method provides a tool for delivery of highly potent, poorly soluble, and unstable APIs. And new in-process capsule printing and shell technologies expand softgels’ applications further.

Conjugated vaccines are meeting the need for longer-lasting immune responses, but the production process is complex, and manufacturers are looking for simpler solutions.

Adoption of single-use systems and more flexible systems drive innovation.

Greater automation and the adoption of solid versus perforated pans are some recent advances.

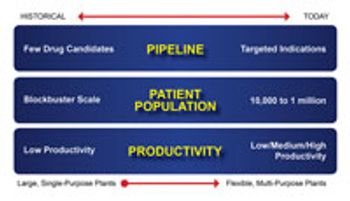

The growing demand for targeted biopharmaceutical therapies is driving interest in modular production facilities that can be rapidly constructed while still minimizing risk and cost.

Dynamic testing and advances in shear testing provide better insight into powder physical properties and external variables that affect powder behavior.

New ion-exchange chromatography media are more tolerant of varying conditions, making it possible to eliminate process steps.

Drug manufacturers today are increasingly challenged to find new, effective methods for the delivery of active pharmaceutical ingredients, and many are discovering that orally disintegrating technologies can help.

Advances in monoclonal antibody separation technologies are largely driven by the need to increase efficiencies and reduce cost.

Drug manufacturers today are increasingly challenged to find new, effective methods for the delivery of active pharmaceutical ingredients, and many are discovering that orally disintegrating technologies can help.

New platform technologies and polymer chemistries may facilitate self-administration, longer-term delivery, and targeted delivery of parenteral drugs.

Effective blenders provide efficient, homogeneous mixing and de-aeration for a wide range of formulations

Podcast interview with Nick Johnson, Strategic Marketing Director for Modified Release Technologies at Catalent Pharma Solutions

Results of an American Chemical Society Green Chemistry Institute Pharmaceutical Roundtable survey found that there is real interest in continuous processing and the use of flow chemistry, but hurdles remain.

New capillary-based imaging techniques for protein charge variant analysis are reducing development and start-up times for protein-based therapeutics.

Because peptoids are relatively easy to synthesize, have tremendous sequence diversity, and are more proteolytically stable than peptides and proteins, they have significant potential for use as APIs, drug-delivery agents, and in numerous biomedical applications.

Increasing production efficiency while ensuring high parenteral product quality is the goal of both manual and automated visual inspection systems.

Effective blenders provide efficient, homogeneous mixing and de-aeration for a wide range of formulations.

As an important method for improving the stability of parenterals, lyophilization is fairly well understood, but can still benefit from several advancements in the technology.

Iterative and multiple incremental advances in particle-characterization technology are making a difference in pharmaceutical analysis applications.

With high productivity achieved, makers of cell-culture media are working to optimize product quality through better understanding and control of raw materials and production processes.

The trick to taste-masking in solid dosage forms is to never let the taste buds have a chance.

Russell Madsen, group leader of the Parenteral Drug Association (PDA) Filtration Interest Group, discusses technical and regulatory considerations in filtration for parenteral drug manufacturing

It can take up to two weeks or more to obtain results from traditional microbiological testing methods. Rapid, automated testing can reduce that time in half.

Although the use of biocatalysis for asymmetric transformations is growing, chemocatalysis remains a highly competitive technology.

Equipment suppliers are helping the pharmaceutical industry move towards adoption of continuous tablet production.

Ensuring the quality of raw materials is a crucial component of achieving product quality of APIs and finished drug products.

Matthieu Egloff, product director with ATMI LifeSciences, discusses the need for larger, special reactors that can provide the necessary conditions for the production of fragile cells on a larger scale.

Collaboration provides pharmaceutical industry customers with access to enzyme expertise and assets resulting in cost-effective, green processing at all phases of development, from preclinical to commercial manufacturing scale.

Ultra high-pressure liquid chromatography (UHPLC) is enabling faster product development and production batch approvals with increased sensitivity.