A recent analysis found that 9000 marketed drugs are not in FDA's National Drug Code Directory.

A recent analysis found that 9000 marketed drugs are not in FDA's National Drug Code Directory.

Whether you advance your technology from concept to commercialization or use a third party for parts or all of this work, the ability to do technology transfer flawlessly is essential to successful, efficient pharmaceutical production.

Efforts to solicit new monographs have fallen behind the rate of NDA approvals, while analytical techniques have become outdated because of advances in analytical technologies.

GlycoFi's work could eliminate the need for mammalian cell culture and improve the performance of protein therapies.

Glasses are important when operating in a sterile environment, and it is necessary to ensure that they will stand up to repeated sterilization processes without introducing contaminants. The glasses were subjected to numerous steam sterilization cycles to assess durability and microbial reduction. Results showed that the glasses most widely available on the market have been refined by the manufacturer to satisfy pharmaceutical customer needs by withstanding repeated sterilization cycles and minimizing contaminating particle release.

More CMOs look to proprietary delivery technologies to enhance profitability.

Much is riding on the market success or failure of Pfizer's Exubera inhalable insulin.

Nondestructive testing takes many forms and is gaining favor because it saves time and prevents costly product loss.

Plastic has emerged gradually as a viable packaging material, even for sterile products. Acceptance of plastics has been encouraged by blow–fill–seal (BFS) technology, which provides scientific and commercial benefits. BFS technology has, however, brought new challenges for formulation-development scientists. This article highlights the specific concerns for the development of sterile liquid products and the formulation strategies to address these concerns.

The authors investigated the influence of various particle size fractions of Tamarind seed polyose (TSP) on indomethacin (IND) release from matrix tablets. They assessed the TSP fractions for swelling, density, and flow properties and the IND matrix tablets for tensile strength, friability, and release profile. Release kinetics was evaluated using Higuchi and Peppas equations. The density and flow properties showed that the size fraction affects the suitability of TSP as an entrapment polymer. The release profile showed that the release of IND from TSP matrix is swelling dependent, thereby affecting the kinetics of release.

Pharmaceutical companies are facing increased competition, cost pressures, and a need to improve the performance of their manufacturing operations. Lean manufacturing offers methods, tools, and heuristics for improved efficiency in manufacturing. Process analytical technology offers alternative analysis techniques that could greatly improve manufacturing quality and efficiency. Mathematical tools exist for assessing the efficiency of manufacturing processes. Internal benchmarking is recommended for determining the efficiency and tracking improvements in pharmaceutical manufacturing.

As custom manufacturers and pharmaceutical ingredient suppliers gather for CPhI Worldwide in Paris, Oct. 3–Oct. 5, industry observers point to a mixed outlook for pharmaceutical custom synthesis. While industry performance for 2006 is better than 2005, the critical question remains the improvement in drug output. The slow rate of approvals of new molecular entities (NMEs) continues in 2006 as Big Pharma seeks to build pipelines of active pharmaceutical ingredients (APIs) through acquisitions, including capabilities in biologics.

Protein formulation specialists have long sensed that something big could be just around the corner. Over the past few decades, countless companies have attempted to bring to market new protein therapeutics that offer improvements-be they more patient friendly, more effective, or easier to manufacture-over traditional formulations. Earlier this year, the launch of Pfizer's "Exubera" pulmonary insulin met this anticipation head on. The fast-acting, inhaled-powder form of recombinant human insulin brought hope to the millions of diabetic patients waiting for an alternative to injections.

Solubility, polymorphism, crystallinity, and crystal habit of acetaminophen and racemic (+/-)-ibuprofen were determined by initial screening of 23 solvents for scale-up. Solubility curves were constructed, and solubility at 25 degrees Celsius was plotted against the dielectric constants of various solvent as a fingerprint for solute identification. The total "form space" for acetaminophen and racemic (+/-)-ibuprofen were calculated to be 222 and 257, respectively. Various crystal habits and sizes for ibuprofen and acetaminophen were observed.

Getting "swamped at work" takes on an entirely new meaning for these GMP Agents.

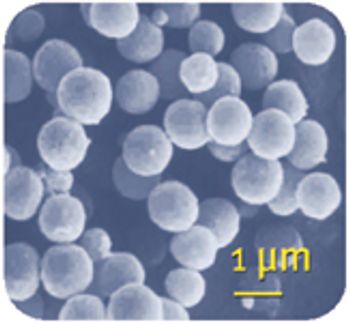

There is a growing need for patient-compliant dosage forms within the cancer therapeutics and biotechnology areas. Ease of administration, enhanced therapeutic efficacy, and reduced side effects are factors that differentiate drug delivery products from conventional dosage forms and provide a competitive advantage. This article reviews salient trends in the parenteral drug delivery sector within the realms of a changing regulatory environment, drivers to growth, and recent advances in this field. Challenges associated with bringing parenteral drug delivery concepts to commercialization are discussed.

Teamwork, communication, and trust are as important as the technology.