Past, Present, and Future Trends Affecting the Bio/Pharmaceutical Industry

The trends in the year 2017 will present the industry with new challenges, and companies will be able to meet them successfully if they focus on the issues at hand.

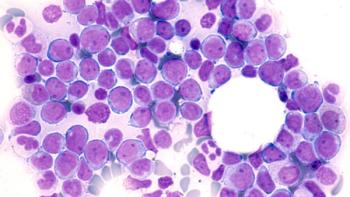

Over the past several years, the global contract pharmaceutical manufacturing market grew at an average annual rate of 7.5% according to the business information portal Visiongain (1). The reason for this growth, among other things, was the growing demand for biotechnological drugs that have established themselves in the treatment of a variety of diseases, as well as the emergence of a number of small pharma companies that have limited capacity to fill their product. And with the global market expected to continue expanding in 2017, the future remains optimistic. According to estimates by the market research firm IMS Health, the market for biological products will reach the $390 billion mark by 2020 (2). It is important to note, however, that companies wanting to exploit this trend will be facing new challenges.

Beginning in 2017, regulatory agencies from many countries will be tightening their guidelines to fight drug counterfeits and are calling for the serialization of drugs in their domestic markets to do so. Using distinctive markings on the sales package, the drugs can be tracked as they pass through the supply chain, from final packaging to distribution, on through to the pharmacy. In some countries such as Turkey, India, China, and Argentina, regulators are already demanding that drugs be serialized. Saudi Arabia and the United States will follow suit in 2017. Starting November 2017, FDA will make serialization of drugs a requirement, with drugs being given a national drug code (NDC), a serial number, a batch number, and a sell-by date. Because serialization requirements differ among countries, pharmaceutical and biotech companies must find flexible solutions that can easily adapt to the demands of individual regulatory authorities.

In the future, international pharmaceutical and biotech companies will be seeking better solutions to predict demand and build flexible supply chains. Because they will be transforming supply-chain management, they must also take digital innovations into consideration such as cloud storage, which has the potential to create a flexible supply chain. In addition, the data gathered from the supply chain can be evaluated and used to make predictions. Production and sales planning can, therefore, be carried out far more accurately using big data analysis.

However, it is not all about software. In coming years, innovative solutions will make it easier to administer drugs to patients. The use of prefilled syringes will increase because they are easier and safer to use, facilitating application and lowering the risk of dosage error. Autoinjectors and pens offer options with even greater convenience. The reason is simple; user convenience is becoming increasingly more important. Patients place high value in applications that they can self-administer. That is why the homecare sector will continue to grow and more medical care will be performed in the home.

The one core challenge that remains for drug manufacturers is digitalization; they will be working hard to develop solutions that make effective use of the digital transformation of the industry. Internal paper-based processes will increasingly be replaced by digital images that will allow for a great deal of potential for improvement. Large amounts of data, widely referred to as big data, will be systematically collected, stored, and analyzed, for example, to ascertain the current status of production orders in real time, or to know the state of a particular machine. Work processes are increasingly being controlled using mobile devices, or even automated.

Pharmaceutical and biotech companies need partners that address their needs in a more personalized manner and support them with custom-designed, flexible solutions and services. They must grapple with the issue of how to innovate and continue to remain a step ahead of the game. Strategic innovation management puts companies in a position to foresee what their customers want, identify process innovations, and implement them. One possibility is working alongside other innovative partners to combine competencies and design new innovation projects.

In the final analysis, there have always been a wide variety of trends that have influenced the bio/pharmaceutical industry. And newer trends will also leave their imprint on the industry in the future, being part and parcel of the economic sector. The trends in the year 2017 will present the industry with new challenges, and companies will be able to meet them successfully if they focus on the issues at hand.

References

1. Visiongain, Pharmaceutical Contract Manufacturing World Market To Reach $79.24bn In 2019, Press Release, February 10, 2015.

2. IMS, Delivering on the Potential of Biosimilar Medicines – The Role of Functioning Competitive Markets (March 2016).

Author: Peter Soelkner is managing director at Vetter Pharma International GmbH.

Newsletter

Get the essential updates shaping the future of pharma manufacturing and compliance—subscribe today to Pharmaceutical Technology and never miss a breakthrough.