Cellares CEO Fabian Gerlinghaus shares how an automated, closed-production platform with a small footprint can dramatically impact cost savings and scalability for cell and gene therapies.

Cellares CEO Fabian Gerlinghaus shares how an automated, closed-production platform with a small footprint can dramatically impact cost savings and scalability for cell and gene therapies.

The company is expanding GMP capacities at its Frankfurt site to manufacture early clinical-phase peptide APIs.

The company is investing more than $250 million into its Bloomington, Ind. Manufacturing site.

CSL will share access to Cytegrity, its proprietary stable production system for lentiviral vector production, with Genezen.

Managing the intricacies of sterile product development is imperative for successful and compliant outcomes.

This article looks at the relationship between a CDMO quality organization and the client.

What do you need to ask during the vetting and selection process to ensure your clinical or commercial program won’t be derailed by a quality-related problem?

The company’s Itasca, Ill., facility will offer chemistry, manufacturing, and controls analytical testing support.

The CDMOs are joining together to offer end-to-end development and manufacturing services for protein expression systems and viral vectors in Europe.

Under a new alliance, KBI Biopharma and Argonaut Manufacturing Services will combine their strengths to offer end-to-end biopharma development and CGMP manufacturing solutions.

Charles River’s off-the-shelf rep/cap plasmids are intended to simplify gene therapy supply chains.

The expansion will boost solid-phase peptide synthesis total reactor volume to 32,000 L.

Andelyn Biosciences has been selected by Ultragenyx to manufacture UX111, that company’s gene therapy for treating Sanfilippo Syndrome.

Following the divestiture of its Elusys subsidiary and other non-core assets, NightHawk Biosciences will transform into a pure-play large-molecule CDMO.

RoslinCT will manufacture Vertex Pharmaceuticals’ CRISPR-based gene therapy, Casgevy, recently approved for treating sickle cell disease and β thalassemia.

Final product inspection results should be included as part of the batch release documentation, says Susan J. Schniepp, distinguished fellow at Nelson Laboratories, LLC.

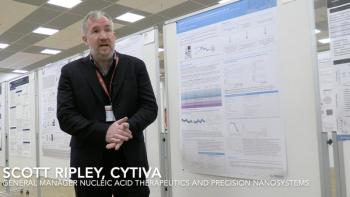

PharmTech Europe discusses technology that enables the “democratization” of mRNA manufacturing with Scott Ripley, general manager, Nucleic Acid Therapeutics and Precision Nanosystems, Cytiva, at the 11th International mRNA Health Conference in Berlin, Germany.

The new centralized hub will provide advanced testing of nucleic acids, which is expected to simplify mRNA substance testing.

As part of a $30 million investment, Aragen is setting up a new biologics manufacturing facility in Bangalore, India.

A new generation of interactive formulation development platforms can leave trial and error in the formulation process in the past.

Sterling is known as a global contract development and manufacturing organization, and their network spreads to a manufacturing site in Cramlington, United Kingdom, a recently GMP-licensed dedicated bioconjugation facility in Deeside, and a 111-acre site in Ringaskiddy, Ireland.

Under an expanded agreement, Cellares will provide proof-of-concept manufacturing for a second CAR-T cell therapy from Bristol Myers Squibb.

The 65,000-square-foot facility is designed with the capacity and capability to help scale the next generation of CGTs for human trials and beyond.

With the acquisition, Sharp plans on offering fully integrated small-to-medium scale sterile injectable services.

The newly established business under Advent International and Warburg Pincus will be named Simtra BioPharma Solutions.