This case study highlights analytical instrumentation and techniques that were used to identify an unknown impurity detected during routine release testing of a topical gel drug product.

This case study highlights analytical instrumentation and techniques that were used to identify an unknown impurity detected during routine release testing of a topical gel drug product.

Advanced analytics and modeling can be used to predict downstream failures, allowing for corrective action before batches are lost.

FDA is encouraging alternative insulins and challenging anticompetitive practices.

Addressing data integrity, quality culture, aging facilities, investigations/corrective actions and preventive actions, and risk management is key when conducting audits, says Susan J. Schniepp, executive vice-president of post-approval pharma and distinguished fellow, Regulatory Compliance Associates.

Biopharma companies responding to the COVID-19 outbreak think accelerating the development of vaccines is safe.

The Nexera UC Prep, a preparative supercritical fluid chromatography (SFC) system from Shimadzu, works to provide maximum use of lab resources through flexible system configurations in a compact design that requires low installation space.

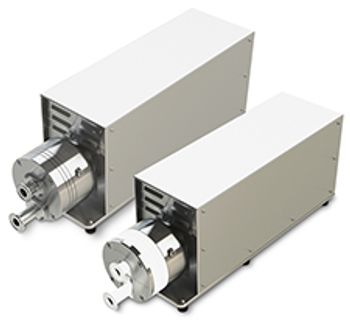

The QF2500 Quaternary Diaphragm Pump from Quattroflow, part of PSG, a Dover company, extends the company’s range of pumps.

The 20,000-gallon storage vessel from Ross Engineering measures at 10.5-ft outer diameter x 30-ft. long and is designed for product storage under atmospheric pressure at 200 ºF; it is UL-142 rated.

Porvair Sciences introduced Microlute SLE 96-well plates and cartridges for the easy extraction of acidic, basic, and neutral analytes from samples, with greater reproducibility.

Because conventional cleaning methods can risk product loss, biopharmaceutical manufacturers are often reluctant to use PDE/ADE limits to validate cleaning processes.

As the coronavirus pandemic unfolds, Pharma must practice science over hype.

With ingredients sold to multiple markets, excipient manufacturers must understand the different regulatory requirements for pharma vs. food.

More sustainable and functional packaging protects temperature-sensitive drugs.

Regulatory emergency planning has been put to the test with the COVID-19 pandemic.

As COVID-19 rapidly spreads, the bio/pharma industry is committing significant efforts to fast track development of therapies.

Considering the potential interaction of a drug with the delivery device early on in in development is integral to achieving the best combination.

The new molecules entering the development pipeline are bringing forth exciting challenges in drug delivery.

Risk levels should be considered when designing containment for pharmaceutical tableting equipment to enhance operator safety.

Pharmaceutical Technology spoke with Jens Andersson, purchasing director at Cambrex Karlskoga, about the best way to ensure the security of the bio/pharmaceutical materials supply chain.

Risk assessments, audits, and good communication between sponsor and supplier are key elements of supplier oversight.

Whether refitting existing spaces or building new, the need for quick build times, flexibility, and production efficiency is driving trends in bio/pharma facility construction.

Click the title above to open the Pharmaceutical Technology April 2020 issue in an interactive PDF format.

But are innovations sufficient to increase adoption? CMOs are demanding better continuous bioprocessing options.